1. Powder Coating Oven for Sale Overview and Structure

A Powder Coating Oven for Sale is a specialized heating system designed to cure powder-coated surfaces on metal substrates. Key components include an insulated chamber, electric or gas heating elements, precision temperature controls, airflow systems, and adjustable racks. Industrial models often feature conveyor belts for automated curing, while compact units suit small workshops.

These ovens are used in automotive manufacturing (for wheels and engine parts), aerospace (aircraft components), furniture (metal frames), and consumer electronics (appliance panels). They ensure scratch-resistant, weatherproof finishes for industrial and commercial products.

Prices range from 5,000forbasicbatchovenstoover100,000 for large conveyorized systems. Mid-tier infrared ovens cost 15,000–40,000, offering faster curing and energy savings. Customizations like extra insulation or advanced controls increase costs by 10–25%.

4. Proper Usage of Powder Coating Ovens for Sale

Preheat the oven to the powder manufacturer’s recommended temperature (typically 160–220°C). Arrange items evenly to allow heat circulation and avoid overloading. Use integrated timers to track curing cycles, and clean the chamber after each use to prevent contamination.

Assess production volume, workspace size, and coating types. High-volume factories benefit from conveyor ovens, while small businesses prioritize batch models. Check certifications (UL, CE) for safety compliance and opt for energy-efficient designs to reduce long-term costs.

Ensure proper ventilation to eliminate toxic fumes. Install fire suppression systems and gas detectors in gas-powered ovens. Operators must wear heat-resistant gloves and goggles. Regularly inspect electrical wiring and heating elements to prevent malfunctions.

Modern ovens use ceramic fiber insulation and heat recovery systems to cut energy use by 30%. Modular designs allow easy upgrades, and smart controllers minimize temperature fluctuations for consistent curing quality.

Q What temperature is ideal for curing powder coatings?

A Most powders cure at 180–200°C, but always follow the supplier’s guidelines.

Q Can I retrofit an existing oven for powder coating?

A Only with proper insulation and temperature controls; dedicated ovens are safer.

Q How long do powder coating ovens last?

A With regular maintenance, industrial ovens operate 10–15 years.

Q Are electric or gas ovens better?

A Electric ovens offer precise temperature control, while gas models are cheaper to run.

Q Do these ovens support custom sizes?

A Yes, many manufacturers build ovens tailored to oversized parts like machinery panels.

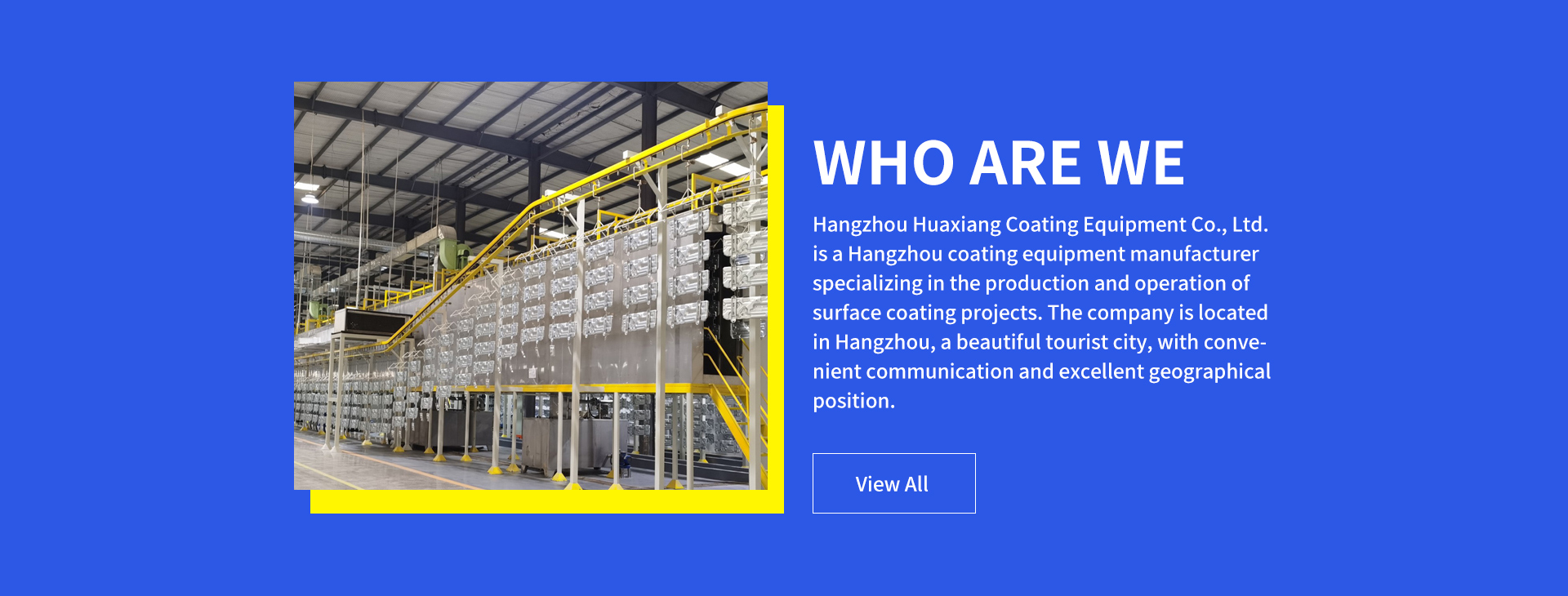

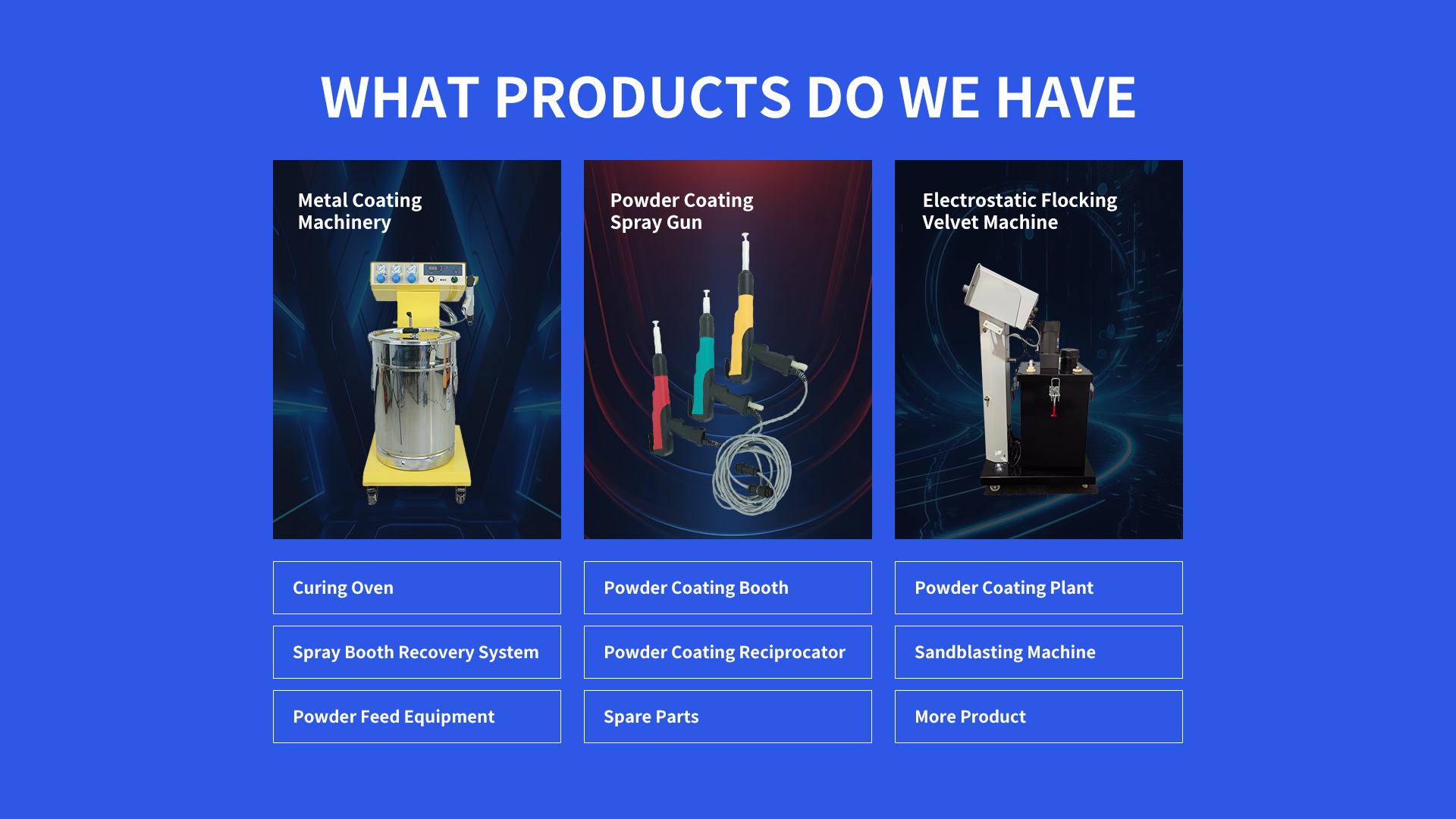

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com